Responsibility

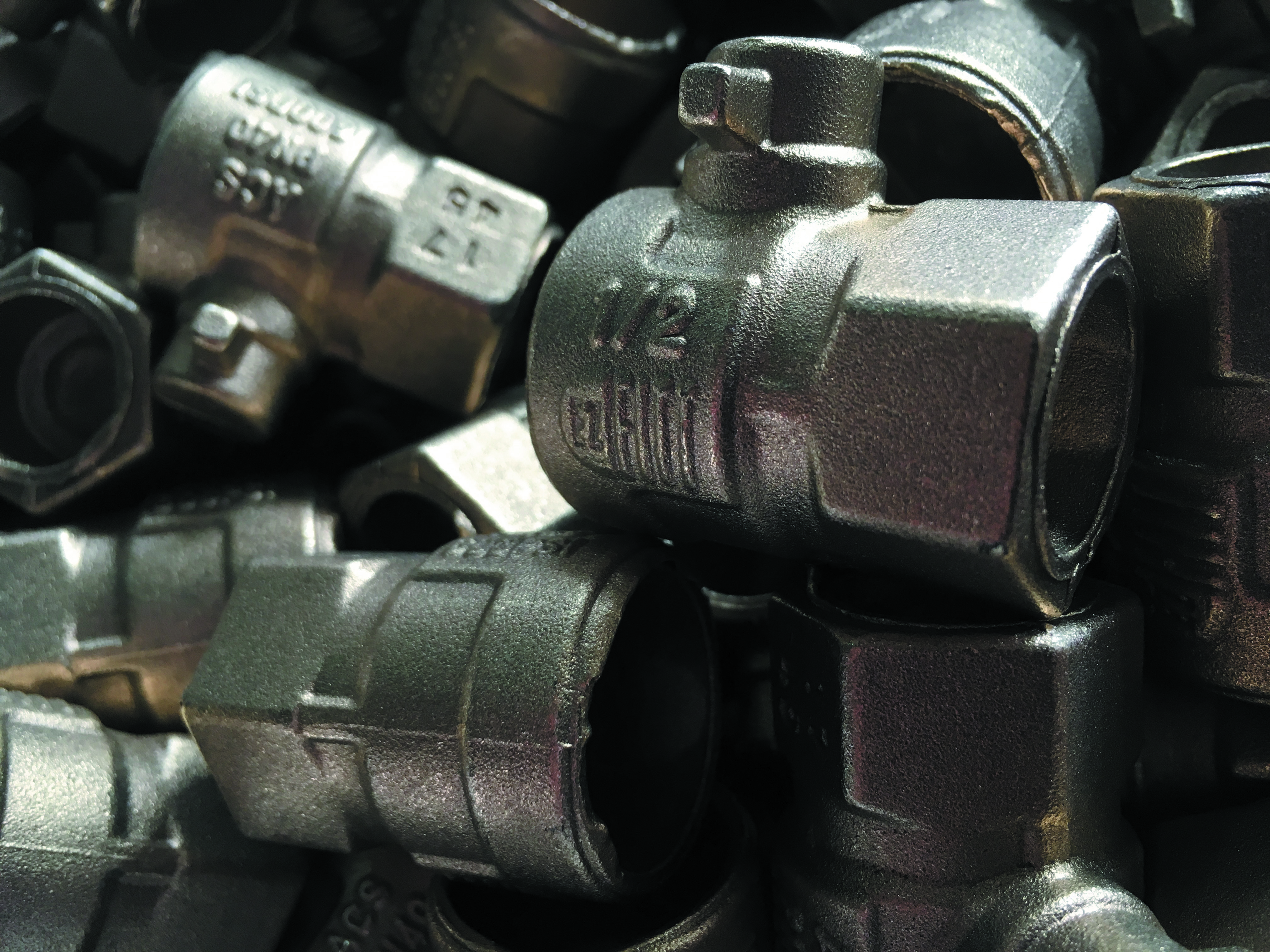

EZFITT is proud to receive the EcoVadis 2023 Bronze Medal, an award that highlights our commitment to sustainability. The EcoVadis label, a global reference in CSR performance evaluation, assesses companies based on four key criteria: environment, human and social rights, and ethics. This medal, obtained after a rigorous evaluation, reflects our determination to combine quality, innovation, and responsibility. It also emphasizes our dedication to integrating eco-friendly practices at every stage of our production process. At EZFITT, we continue to strive for a more sustainable future while maintaining our high standards of excellence.

Our environmental strategy focuses on reducing energy consumption and improving waste management, aiming to conserve natural resources. We are implementing concrete actions to minimize our environmental impact.

Regarding social issues, we actively promote social diversity and condemn any form of discrimination or harassment within our workplace. We ensure that all our employees work in a respectful and safe environment, guaranteeing equal opportunities for everyone.

Finally, we are committed to establishing ethical and transparent business relationships. We make every effort to ensure that our professional relationships are long-lasting by partnering with those who share the same values. This is why we prioritize partners who also adopt a responsible approach, contributing to sustainable and fair development.